In brief

- Modern system testing is done on individually designed test benches, requiring both testing and system design knowledge

- As the amount of simulation data and testing effort soars, this approach becomes unmanageable

- Adaptix's novel drawer-based modular HiL systems offer a new and improved test bench handling

A day in the life of a tester can be arduous, especially when it comes to testing an advanced driver assistance system (ADAS). So, at least the testing lab equipment should be easy to handle and maintain — our modern and modular data center makes testing enjoyable and efficient. The challenge: Ever-changing requirements from clients in the field of modularization and standardization make it increasingly difficult to keep the system simple.

ADAS testing requires the re-injection of ground truth data to improve the performance of its sensors. With the increasing demands of today’s ADAS technology, the requirements on the replay process and its complexity are also growing. The test effort rises disproportionately with AD functionality advancing from SAE Level 1 to 5. So, managing the complexity of the test systems on both the software and hardware side is crucial.

A widely used method to test such systems is the Hardware-in-the-Loop (HiL) simulation, which enables the stimulation of the device under test (DUT) with ground truth sensor data. Usually, each use case requires an individually designed HiL environment that matches the demanded data volumes and simulation efforts. This makes handling and maintenance difficult and time-consuming.

The solution: HiL in the drawer

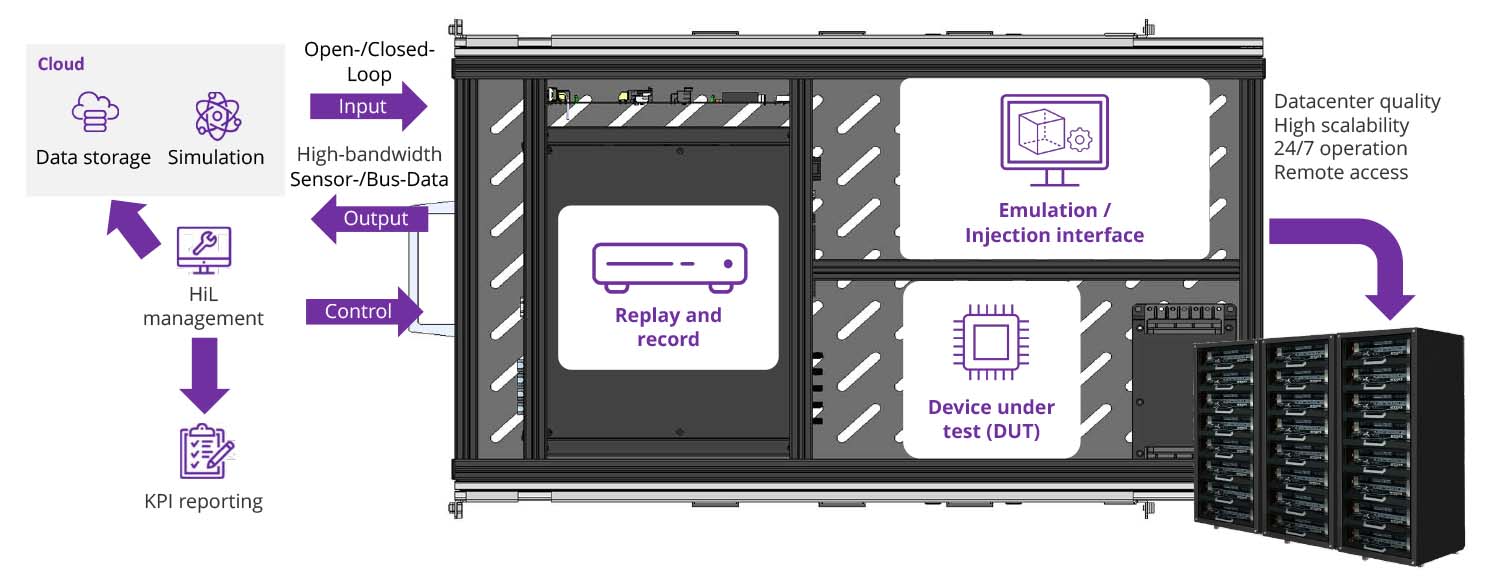

ADAPTIX has conceived a simpler and more timesaving approach: Standardized HiL systems that are easier to maintain and even scalable. For this concept, Adaptix Solutions ideated modular hardware components. Together with our trusted partner b-plus, we designed a solution that enables high flexibility and empowers Adaptix Solutions’s vision of automated testing while reducing the manual efforts for design and adjustment of HiL systems: The CONiX HiL Solution.

How HiL drawers can save the day

Look how much easier your testing life can be with the right equipment.

Death of the module

It’s not a nice thought, but it happens: Your HiL-module has been damaged and has died. Normally, you would have to organize a spare part, or even set up a whole new system. This is time-consuming and ineffective.

With the Adaptix Solutions CONiX HiL Solution, you benefit from high flexibility — the simulation can simply be transferred to another drawer and the one with the damaged module can be replaced with a new drawer from stock. So, the simulation process can be instantly pursued.

Scale me up or down

Does your simulation need a higher real-time factor? In a conventional setup you would need to set up a completely new system — meaning lots of additional effort for design and build-up — because no up- or down-scaling is possible within the system.

The CONiX HiL Solution can be up-scaled ad hoc by simply adding an additional drawer to the system. The unified scheme drawers can be stored in stock and deployed upon request. The easy plug in/plug out principle allows for high scalability. Whenever the number of test cases or scenarios changes, the HiL can be reconfigured immediately. With this approach, the realization of a lower real-time factor can also be achieved.

Keep cool and power on

With HiL testbenches, the threat of overheating is omnipresent. Because overheating may cause considerable damage, the correct placement of the power supply and its sufficient cooling is crucial. This needs to be considered during the design of a HiL, requiring specific electromechanical and thermodynamic know-how, which is always an issue when it comes to calculating cooling efficiency for data centers.

A redundant power supply and a bypassing, integrated cooling for every drawer eliminates this problem in a CONiX HiL Solution, resulting in an easy-to-operate bench with no additional effort for design and integration of cooling systems.

Just do it

For conventional setups, a deep understanding of hardware is required to design, build and adapt a HiL. Typical HiL operators do not have this extensive mechanical knowledge.

With a managed CONiX HiL Solution, operators do not need knowledge about HiL construction — everyone can plug in or unplug a drawer.

Everything everywhere all at once

Consider a storage device with new data. It has just arrived from the latest test drive and should now be used for simulations. To connect the HiL with new data storage, the system must be accessible. Typically, it is located on a laboratory bench, where testers are simulating directly on the HiL when results of other data or test cases are requested.

In contrast, the CONiX HiL Solution can be up-scaled to a large and powerful system consisting of many drawers with room for huge datasets, but it will never waste space in your lab because it can be moved to the server room. Due to its remote accessibility, new data can be included from anywhere in the world over the cloud. As the HiL system is accessible and manageable remotely via Network File System (NFS), the simulation can also be triggered remotely or scheduled in advance.

System design makes the difference

As we have seen, the CONiX HiL Solution can be set up with low effort due to the standardization of its drawers and it offers an optimized mode of operation of sensor systems for ADAS technology. The compact and modular design of the drawer system avoids the tangling of cables and simplifies maintenance.

All kinds of configurations are possible: From a single drawer system, up to a powerful HiL with enormous bandwidth. The system can also be applied to various use cases: For managing Hardware-open-Loop (HoL) and Pseudo open-Loop (PoL) solutions and farms or — with an additional camera data stream — as test data.

Lean back and rely on the available, tested drawer modules instead of worrying about the next HiL design.

New features coming soon

The drawer setup is being constantly updated. Its software is continuously improved; feature- and security-updates will be made available regularly.

And we are already working on incorporating machine learning algorithms. This will open a whole new range of use cases and even more support and assistance for the testers.

So, next time you are planning a HiL setup, opt for our drawer-based one, it’ll make your life easier. Contact us for configuration options and more resources.